Clean Beauty, Ingredients, Reviva Labs, Skin Care

New Preservation Choices Shaping Modern Skincare

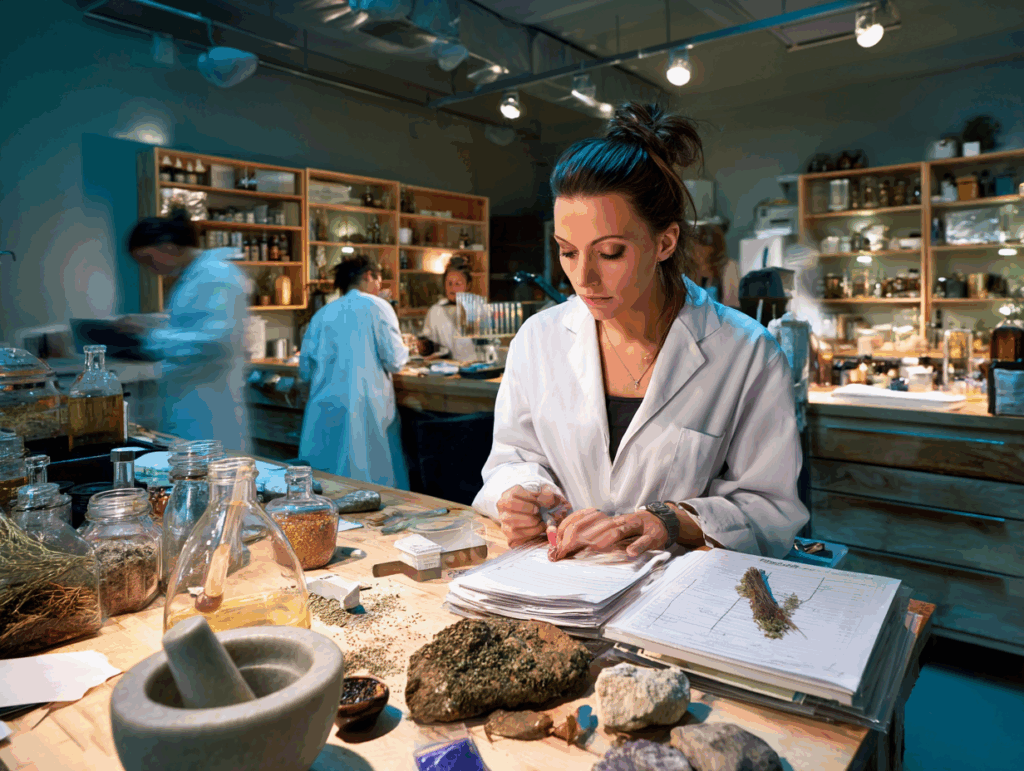

One detail defines the work of every skincare formulator. Microbial contamination continues to trigger a significant share of cosmetic recalls in global regulatory databases, and it increases the pressure on brands to choose stronger and safer preservation strategies. You cannot build a stable cream, serum, or cleanser without thinking about how microbes behave once water, oils, and actives come together. You also cannot ignore the steady shift toward formulas built from milder, plant-derived, and multifunctional ingredients. That shift has placed new attention on preservatives that promise safer profiles and lighter sensory effects. Glyceryl caprylate and glyceryl undecylenate sit at the center of that movement, offered together as Lexgard Natural MB, and many formulators now compare them to the long-standing blend of phenoxyethanol and ethylhexylglycerin. The comparison matters, because choosing the wrong preservative system can break a formula no matter how well the rest of the ingredients perform.

Formulators face competing pressures from several directions. You want broad microbial coverage, so the formula stays safe from bacteria, yeast, and mold during its entire shelf life. You also want clean sensory behavior, so the finished product feels elegant. On top of this, you hear constant consumer demand for gentler formulas with simple ingredient lists. Retailers add more restrictions each year. That tension has pushed the industry toward new options that aim to satisfy both performance and marketing needs. Glyceryl caprylate and glyceryl undecylenate represent this new model, so a closer look at how they function helps explain when they succeed and when they struggle.

Phenoxyethanol and ethylhexylglycerin have a long record of effectiveness, so they serve as a benchmark. The pairing covers bacteria well, supports fungal resistance with help from ethylhexylglycerin, and stays active across the pH ranges common to most skincare products. It also behaves predictably in a wide range of formats, from serums to lotions to wipes. This reliability created a generation of products built around the blend. But it also placed phenoxyethanol at the center of ongoing debate. Some retailers restrict it, and some consumers question synthetic preservation systems. That dynamic opened the door for plant-derived alternatives, which is why glyceryl esters gained traction.

Why preservative innovation is gaining speed

Glyceryl caprylate and glyceryl undecylenate share structural similarities. They are monoesters made by bonding glycerin with fatty acids. Their origins can be renewable, and their profiles appeal to brands that want sustainable or nature-linked ingredient stories. They are also multifunctional. They support emulsion structure, improve spread, and contribute to a softer feel in both water-in-oil and oil-in-water systems. These characteristics set them apart from single-purpose preservatives. They do not simply defend against microbes. They also shape texture in a subtle but useful way, which makes them attractive in modern formulas that aim for cleaner ingredient lists.

The growing interest comes from more than their sourcing. It comes from the way they influence microbial activity. Glyceryl caprylate targets bacteria by disrupting membranes. Glyceryl undecylenate brings stronger antifungal strength because of its ricinoleic origin. When used together, they extend coverage and allow the formulator to build a preservation system that feels lighter and more skin-friendly than harder synthetic options. This makes them appealing in serums rich in botanical extracts or creams designed for sensitive skin.

The shift toward these esters, however, brings tradeoffs. Their performance depends on pH control, water activity, and supporting ingredients. They do not behave like phenoxyethanol, which holds its performance across many formula types with fewer constraints. This means the formulator must plan from the start to protect these esters from conditions that weaken them. It also means testing must begin early, because performance varies more when the surrounding formula uses botanicals, proteins, or actives with sensitivity to pH drift.

As consumer expectations continue to favor milder formulas, these systems gain visibility. But they also raise questions about whether they can replace legacy materials entirely. That question cannot be answered with a simple yes or no. It depends on how the formula behaves, how the product is packaged, and which markets the brand wants to enter. Natural retailers often restrict phenoxyethanol. Conventional retailers do not. This means your preservative choice influences your distribution strategy. That alone is enough to require deeper evaluation before committing to a system.

The strengths of glyceryl caprylate in modern formulas

Glyceryl caprylate shines because it supports several goals at the same time. It acts as a mild antimicrobial booster, an emulsion stabilizer, and a skin-conditioning agent. Its amphiphilic nature allows it to sit at the oil water interface. That position gives it influence over droplet structure and overall texture. It can reduce the need for heavier emulsifiers and still keep viscosity predictable. For a formulator who wants a cream that feels elegant rather than heavy, this is a noticeable advantage.

Its preservation function comes from its ability to reduce bacterial growth. It performs best in acidic environments that match the natural pH of the skin. This match helps the ingredient feel intuitive in formulas that focus on barrier comfort. When paired with glyceryl undecylenate, the system expands its reach. But glyceryl caprylate alone still needs help to keep formulas safe. Water-rich systems encourage bacteria. Humectants further increase water activity. If the surrounding formula does not contain stabilizing elements, glyceryl caprylate struggles. This creates a need for precise pH control and thoughtful pairing with chelators or co-preservatives.

In well-designed formulas, glyceryl caprylate brings a cleaner ingredient list. It reduces the need for multiple supporting agents. It softens the overall sensory experience. These qualities match natural brand positioning. They also match current consumer expectations around gentle formulas. But these benefits arrive only when the formulator creates the right stability environment. That means early challenge testing, careful manufacturing, and attention to packaging. Droppers introduce more oxygen exposure. Jars introduce more contamination risk. Pumps reduce those risks. The preservative system must match the packaging as much as it matches the ingredient deck.

Glyceryl caprylate also interacts differently with botanical actives. Some plant extracts introduce natural enzymes that encourage microbial growth, and some bring pH drift over time. These interactions influence how well a glyceryl-based system performs. This increases development time because the system does not automatically tolerate such variability. A formulator must adjust early or redesign the formula to keep everything stable.

How glyceryl undecylenate supports broader protection

Glyceryl undecylenate fills the largest gap left by glyceryl caprylate. Its structure gives it natural antifungal strength, which becomes essential in formulas containing oils, waxes, plant butters, or botanical ferments. These formulas have increased risk of fungal contamination because fungi thrive in nutrient-dense, slightly acidic environments. Glyceryl undecylenate delivers stronger protection in those scenarios.

Its behavior also supports natural brand storytelling. It comes from castor oil, and many natural certifying organizations view this origin favorably. The ingredient pairs smoothly with glyceryl caprylate, creating a system capable of meeting many clean-beauty requirements. It also adds mild skin-conditioning attributes, which keeps the overall formula pleasant.

The challenges emerge in formulas with higher pH. Glyceryl undecylenate loses potency above the mid five range. This restricts the system’s use in certain formats. Some masks and cleansers operate closer to neutral pH. Some emulsions drift upward over time because of natural extracts or fatty alcohols. These shifts weaken the preservative’s reach. The system can still work in such formulas, but only if the formulator compensates with additional components. This adds complexity to formulas that aim for minimalist ingredient lists.

Another factor involves high water activity. If a formula contains a large percentage of water without additional humectants or texture-builders, glyceryl undecylenate alone cannot hold back microbial growth fully. It must work with glyceryl caprylate and possibly extra support. This does not reduce its value. It only means that a natural preservation system demands a more structured formula design.

When conditions align, glyceryl undecylenate becomes an effective partner. It creates broader antimicrobial coverage and improves performance in botanical or oil-heavy formulas. But formulators must control pH from the earliest stages. They must also account for texture changes that occur during filling and cooling. These variables influence how the preservative disperses.

The enduring performance of phenoxyethanol systems

Phenoxyethanol and ethylhexylglycerin remain two of the most stable and predictable preservation tools available. Phenoxyethanol delivers strong bacterial protection. Ethylhexylglycerin enhances its reach while reducing potential irritation. The pair functions across a wide pH range. It tolerates botanical extracts. It handles temperature swings during shipping. It holds its activity in nearly every common skincare format. This makes the system the least risky choice in large-scale commercial formulation.

Ethylhexylglycerin softens sensory impact by improving glide and reducing tightness in water-rich formulas. It also supports preservation without introducing harshness. The blend carries decades of safety data and survives strict challenge testing with fewer formula adjustments. This predictability shortens development cycles. Brands working with wide SKU ranges often choose this system because it ensures consistency from batch to batch.

The limitations show up in marketing contexts rather than performance. Some retailers restrict phenoxyethanol. Some shoppers want formulas without synthetics. This creates a conflict between technical reliability and consumer preference. The system also introduces a faint scent in some fragrance-free formulas. The effect varies, but chemists often notice it when working on minimalist products. These details do not reduce its stability, but they influence its acceptance in specific markets.

Phenoxyethanol systems also handle disruptive actives more easily. Strong acids, vitamin C derivatives, peptides, and retinoids often change formula pH over time. They also encourage oxidative stress. Phenoxyethanol tolerates these variables without losing much potency. This gives formulators more freedom to build complex serums without redesigning the preservation strategy.

For these reasons, phenoxyethanol and ethylhexylglycerin outpace most natural alternatives in reliability. The system does not need precise pH control and does not restrict formula structure. It remains the easier choice when safety and consistency take priority.

What natural preservative systems mean for formulators

The rise of natural preservative systems does not signal the decline of synthetic ones. It signals diversification. Modern brands target broad audiences. Some value scientific track records. Some value plant-derived ingredients. Some want minimalist lists. Some want maximal performance. No single preservation system can satisfy all of these demands, so formulators choose based on strategy rather than preference.

Glyceryl caprylate and glyceryl undecylenate meet the needs of formulas that emphasize gentleness and simple ingredient decks. They fit natural certifications when paired with compatible ingredients. They support emulsions while protecting them. They also bring sensory improvements. Their limitations do not come from weakness. They come from structural sensitivity. They need controlled pH. They need support from chelators. They need packaging that reduces contamination risk. They need careful challenge testing from the earliest stages.

Phenoxyethanol and ethylhexylglycerin meet the needs of formulas that require broad antimicrobial coverage with minimal constraints. They hold up across many conditions. They tolerate complex ingredient systems. They simplify manufacturing and reduce risk during scale-up. Their main limitation is consumer perception and retailer restrictions.

Organic acids, ferment filtrates, and other natural antimicrobial agents continue to rise. They expand the possibilities for natural-focused brands. They also encourage more creative approaches to texture, water activity reduction, and packaging. But most still need partners to deliver full coverage. They also behave differently across pH windows. Their performance varies more than synthetic systems.

This landscape proves one point. Preservation is not a plug-and-play step. It demands equal attention to formula design, packaging, manufacturing, and marketing intent. If you shift any part of the structure, the preservative must shift with it. That is why the best preservative is not the one that appears most natural or most powerful. It is the one built intentionally for the formula it protects.